- Nehru Place, Delhi

- View Mobile Number

Binders

| Business Type | Manufacturer, Exporter, Supplier |

| Size | 45x60cm |

| Application | Office,School,Home |

| Surface | 1.2mm Cork Surface |

| Weight after packing | 1.1kg |

| Shelf life | 2 Year |

| Total thickness | 1.16cm |

A binder for cork board is a specialized adhesive designed to bond cork to various substrates, providing a strong, durable hold. Ideal for use in creating cork bulletin boards, cork wall coverings, and other cork-based applications, this adhesive ensures the cork remains securely attached and maintains its structural integrity over time.

Key Features:

Strong Adhesion: Provides excellent bonding strength to cork and a variety of substrates such as wood, metal, and drywall.

Easy Application: Typically comes in a user-friendly format, such as liquid or spray, making it easy to apply evenly.

Quick Drying: Fast drying times help speed up the installation process, reducing wait times.

Durability: Resistant to aging, moisture, and temperature fluctuations, ensuring the bond remains strong over time.

Low VOC: Formulated to be low in volatile organic compounds (VOCs), making it safer for indoor use and environmentally friendly.

Applications:

Bulletin Boards: Ideal for attaching cork sheets or tiles to create functional and decorative bulletin boards.

Wall Coverings: Suitable for installing cork wall panels, providing a sound-absorbing and aesthetically pleasing finish.

Craft Projects: Perfect for various DIY and craft projects involving cork.

Summary:

A binder for cork board is a versatile adhesive that provides a reliable and durable bond for cork applications. Its strong adhesion, easy application, quick drying time, and environmental safety make it an essential tool for both professional and DIY installations of cork surfaces.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Polyuerthane |

| Application | Construction,Packing,Transportation,Woodworking |

| Size | Etc. |

| Classification | Other Adhesives |

| Shelf life | 12 Months |

Binders for rebounded foam are specialized adhesives used to bond shredded or ground foam pieces together to form rebounded foam products. These binders ensure that the foam particles are securely adhered, creating a durable, resilient, and cohesive material ideal for various applications.

Key Features:

High Bond Strength: Provides robust adhesion, ensuring the foam particles are tightly bound together for maximum durability.

Flexibility: Maintains flexibility and resilience of the foam, allowing the finished product to withstand compressive forces and repeated use.

Fast Curing: Offers quick curing times to speed up the manufacturing process and increase production efficiency.

Durability: Resistant to wear and tear, temperature fluctuations, and moisture, ensuring long-lasting performance of the rebounded foam.

Low VOC: Formulated to be low in volatile organic compounds (VOCs), making it safer for workers and environmentally friendly.

Applications:

Carpet Padding: Ideal for producing rebounded foam underlays for carpets, providing cushioning and noise reduction.

Furniture: Used in the manufacturing of rebounded foam cushions for furniture, offering comfort and support.

Athletic Mats: Suitable for creating durable and resilient mats for gyms and sports facilities.

Packaging: Used in protective packaging solutions where shock absorption is critical.

Summary:

Binders for rebounded foam are essential adhesives that provide strong, durable, and flexible bonds for rebounded foam products. With features like high bond strength, fast curing, and low VOC content, these binders are crucial for producing high-quality, resilient foam products used in various industries including flooring, furniture, sports, and packaging.

| Business Type | Manufacturer, Exporter, Supplier |

| Color | White |

| Feature | Heat Resistant |

| Grade Standard | Chemical Grade |

| Purity (%) | 99 |

| Form | Liquid |

| Density (g/cm Cube) | 1.10 +/ 0.5 @ 25 degree C |

NEOSOL Binder is a high-quality adhesive specifically formulated for bonding EPDM granules and other rubber particles in the construction of synthetic sports surfaces and playgrounds. This versatile binder ensures a durable, resilient, and weather-resistant surface, ideal for various applications.

Key Features:

Superior Adhesion: Provides excellent bonding strength, securely binding granules and particles to create a cohesive surface.

Flexibility and Elasticity: Maintains flexibility, allowing the surface to absorb impacts and reduce stress on users' joints.

Weather Resistance: Formulated to withstand harsh weather conditions, including UV exposure, moisture, and temperature variations.

Fast Curing: Quick curing properties facilitate faster installation and minimal downtime.

Low VOC: Environmentally friendly formulation with low volatile organic compound content, ensuring safety for installers and users.

Applications:

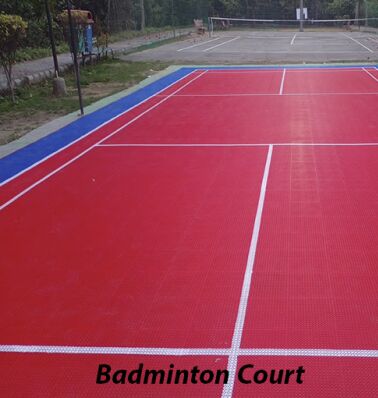

Running Tracks: Ideal for creating all-weather running tracks that offer consistent performance and safety.

Playgrounds: Suitable for constructing durable and safe playground surfaces.

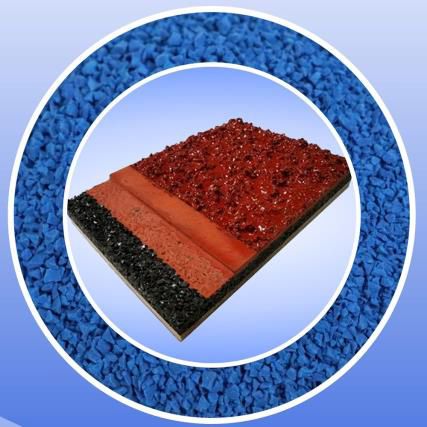

Sports Courts: Perfect for various sports courts, including tennis and basketball, requiring high-performance surfaces.

Multi-Purpose Athletic Fields: Used in multi-use fields, providing a versatile and resilient surface for different sports activities.

Summary:

NEOSOL Binder is a robust and versatile adhesive designed to create durable and high-performance synthetic sports surfaces. Its superior adhesion, flexibility, weather resistance, and fast curing make it an ideal choice for applications like running tracks, playgrounds, sports courts, and multi-purpose athletic fields.

| Business Type | Manufacturer, Exporter, Supplier |

| Physical State | Liquid |

| Usage/Application | Industrial |

| Grade Standard | Industrial Grade |

| Country of Origin | Made in India |

| item Code | neosportn-track37 |

The N-Track-37 system is an advanced, high-performance solution designed to provide optimal surfaces for running tracks. This system combines the benefits of a coating and sealant sandwich to create a durable, safe, and resilient track surface that meets the demands of athletes and sports facilities.

Key Features

1. Durability:

o Wear Resistance: The system is engineered to withstand heavy use and harsh weather conditions, ensuring a long lifespan for the track.

o UV Stability: Resistant to UV radiation, preventing degradation and color fading over time.

2. Safety:

o Slip Resistance: Provides a non-slip surface, reducing the risk of injuries.

o Impact Absorption: Designed to absorb impact, minimizing stress on athletes' joints and muscles.

3. Performance:

o Consistent Surface: Ensures a smooth and consistent running surface for optimal athletic performance.

o Excellent Traction: Offers superior grip, enhancing athletes' performance and reducing the likelihood of slips.

4. Aesthetic Appeal:

o Color Options: Available in various colors, allowing for customization to match team or facility colors.

o Finish Quality: Delivers a high-quality finish that enhances the visual appeal of the track.

5. Environmental Resistance:

o Waterproofing: The sealant layer provides excellent waterproofing, protecting the underlying surface from moisture damage.

o Chemical Resistance: Resistant to common chemicals and substances, ensuring longevity and low maintenance.

System Composition

1. Base Layer:

o Comprised of a stable, resilient base that provides the foundational support for the track. Often made from recycled rubber materials to enhance shock absorption and sustainability.

2. Intermediate Coating Layer:

o A specialized coating that enhances adhesion between the base and top layers. This layer ensures that the surface remains intact and prevents delamination.

3. Top Sealant Layer:

o A high-performance sealant that provides the final surface. This layer is designed to be wear-resistant, UV stable, and waterproof, ensuring that the track remains in optimal condition.

Installation Process

1. Surface Preparation:

o The existing surface is cleaned and prepped to ensure proper adhesion of the N-Track-37 system.

2. Base Layer Application:

o The base layer is applied and leveled to create a stable foundation.

3. Intermediate Coating Application:

o The intermediate coating is applied to ensure strong adhesion between layers.

4. Top Sealant Layer Application:

o The top sealant layer is applied, providing the final durable and attractive surface.

5. Curing and Finishing:

o The system is allowed to cure properly before final inspections and markings are added.

Benefits

- Longevity: The combination of coating and sealant provides enhanced durability and a longer lifespan compared to traditional track surfaces.

- Low Maintenance: The high resistance to wear, weather, and chemicals means less frequent repairs and maintenance.

- Athlete Performance: Provides a safe and consistent surface that helps athletes perform at their best.

- Environmental Sustainability: Utilizes recycled materials and provides long-term environmental benefits through reduced maintenance needs.

- N-

| Business Type | Manufacturer, Exporter, Supplier |

2 Component Spray Coat Systems for Running Tracks

Description-

Overview

N-Track 64 is an advanced, two-component spray coating system designed specifically for the construction and maintenance of running tracks. This system provides a seamless, durable, and high-performance surface that meets the rigorous demands of athletic activities. It is ideal for professional sports facilities, schools, and recreational areas.

Key Features

1. Durability:

o Wear Resistance: Formulated to withstand heavy foot traffic and athletic activities, ensuring a long-lasting surface.

o Weather Resistance: Excellent resistance to various weather conditions, including UV radiation, rain, and temperature fluctuations.

2. Safety:

o Slip Resistance: Provides a non-slip surface, reducing the risk of injuries for athletes.

o Impact Absorption: Designed to absorb impact, minimizing stress on athletes' joints and muscles.

3. Performance:

o Consistent Surface: Ensures a smooth and consistent running surface for optimal athletic performance.

o Excellent Traction: Offers superior grip, enhancing athletes' performance and reducing the likelihood of slips.

4. Aesthetic Appeal:

o Color Options: Available in various colors, allowing for customization to match team or facility colors.

o Finish Quality: Delivers a high-quality finish that enhances the visual appeal of the track.

5. Environmental Resistance:

o Waterproofing: The spray coating provides excellent waterproofing, protecting the underlying surface from moisture damage.

o Chemical Resistance: Resistant to common chemicals and substances, ensuring longevity and low maintenance.

System Composition

1. Component A:

o Typically a polyol blend that acts as the reactive base of the coating system.

2. Component B:

o Generally an isocyanate that reacts with Component A to form a durable polyurethane coating.

Application Process

1. Surface Preparation:

o Cleaning: Ensure the existing surface is clean, dry, and free from dust, dirt, oil, and other contaminants.

o Priming: Apply a primer if necessary, to enhance adhesion between the existing surface and the new coating.

2. Mixing:

o Component Mixing: Mix the two components (A and B) according to the manufacturer’s instructions, ensuring thorough mixing for a consistent and reactive blend.

3. Application:

o Spray Application: Use a specialized spray equipment to apply the mixed coating onto the track surface. Ensure even and consistent application to achieve the desired thickness.

o Layering: Multiple layers may be applied to achieve the required surface properties and thickness.

4. Curing:

o Setting Time: Allow the coating to set and cure according to the specified curing time. Avoid any traffic or movement on the track during this period.

o Final Inspection: After curing, inspect the track surface to ensure complete and even coverage, making any necessary touch-ups.

- Benefits

- Longevity: The durable formulation provides a long-lasting surface that can withstand intense use and various environmental conditions.

- Low Maintenance: The high resistance to wear, weather, and chemicals means less frequent repairs and maintenance.

- Enhanced Performance: Offers a safe and consistent surface that helps athletes perform at their best.

- Aesthetic Quality: Maintains its appearance and functionality over time, enhancing the overall look of the track facility.

- Technical Specifications

- Mixing Ratio: Specified by manufacturer (typically 1:1 or as recommended).

- Pot Life: Adequate working time for application (varies based on environmental conditions).

- Curing Time: Typically ranges from several hours to a day, depending on temperature and humidity.

- Application Temperature: Recommended temperature range for optimal performance.

| Business Type | Manufacturer, Exporter, Supplier |

2 Component Sealant Coating for Running Track Systems & Sealing Layers

Description-

Overview

N-Track 91 is an advanced, two-component sealant coating system specifically formulated for the sealing and finishing of running track surfaces. This system provides exceptional durability, flexibility, and weather resistance, ensuring a high-performance and long-lasting track surface. It is ideal for use in professional sports facilities, schools, and recreational areas.

Key Features

1. Durability:

o Wear Resistance: Engineered to withstand heavy foot traffic and the rigors of athletic activities, ensuring longevity.

o Weather Resistance: Offers excellent protection against UV radiation, rain, and extreme temperature variations.

2. Safety:

o Slip Resistance: Provides a non-slip surface to reduce the risk of injuries for athletes.

o Impact Absorption: Designed to absorb impact, minimizing stress on athletes' joints and muscles.

3. Performance:

o Seamless Surface: Creates a smooth, consistent surface that enhances athletic performance.

o Excellent Traction: Delivers superior grip, improving safety and performance during athletic activities.

4. Aesthetic Appeal:

o Color Stability: Available in various colors with UV stable pigments that prevent fading and discoloration over time.

o High-Quality Finish: Provides a visually appealing finish that enhances the look of the track.

5. Environmental Resistance:

o Waterproofing: Forms a waterproof barrier that protects the underlying layers from moisture damage.

o Chemical Resistance: Resistant to common chemicals and substances, ensuring a long-lasting surface with minimal maintenance.

System Composition

1. Component A:

o A polyol blend that serves as the reactive base of the coating system.

2. Component B:

o An isocyanate that reacts with Component A to form a robust polyurethane sealant coating.

Application Process

1. Surface Preparation:

o Cleaning: Ensure the surface is clean, dry, and free from dust, dirt, oil, and other contaminants.

o Priming: Apply a primer if necessary, to enhance adhesion between the existing surface and the sealant coating.

2. Mixing:

o Component Mixing: Mix Components A and B according to the manufacturer’s instructions. Ensure thorough mixing to achieve a consistent and reactive blend.

3. Application:

o Application Method: Use suitable tools such as rollers, squeegees, or spray equipment to apply the mixed coating. Ensure even and consistent application to achieve the desired thickness.

o Layering: Multiple layers may be applied to build up the required thickness and performance properties.

4. Curing:

o Setting Time: Allow the coating to cure according to the specified curing time. Avoid traffic or movement on the track during this period.

o Final Inspection: After curing, inspect the surface to ensure complete and even coverage, making any necessary touch-ups.

Benefits

- Long-Lasting Performance: Provides a durable and resilient surface that can withstand intense use and various environmental conditions.

- Low Maintenance: High resistance to wear, weather, and chemicals reduces the need for frequent repairs and maintenance.

- Enhanced Safety: Offers a safe, non-slip surface that reduces the risk of injuries and enhances athlete performance.

- Aesthetic Quality: Maintains its appearance and functionality over time, contributing to the overall appeal of the track facility.

- Technical Specifications

- Mixing Ratio: Specified by manufacturer (typically 1:1 or as recommended).

- Pot Life: Adequate working time for application (varies based on environmental conditions).

- Curing Time: Typically ranges from several hours to a day, depending on temperature and humidity.

- Application Temperature: Recommended temperature range for optimal performance.

| Business Type | Manufacturer, Exporter, Supplier |

| Color | Green |

| Application | Plastic Sealing,Artificial |

| Type | Plastic Adhesives |

| Country of Origin | India |

| Cas Number | N Turf 19 |

(Multipurpose Two-Component Artificial Grass Adhesives)

N TURF 19 is a high-performance, two-component adhesive specifically designed for the installation of artificial grass and synthetic turf. This adhesive ensures a strong, durable bond between the turf and the substrate, providing excellent performance in various environmental conditions.

Key Features:

Two-Component System: Comprises a resin and a hardener that, when mixed, form a robust adhesive bond suitable for demanding applications.

High Bond Strength: Offers superior adhesion to artificial grass backing and a variety of substrates, including concrete, asphalt, and compacted aggregate bases.

Weather Resistance: Formulated to withstand extreme weather conditions, including UV exposure, rain, and temperature variations, without compromising the bond.

Versatility: Suitable for a wide range of applications, including sports fields, landscaping, playgrounds, and recreational areas.

Long Working Time: Provides adequate working time for precise placement and adjustment of turf, ensuring a professional finish.

Environmental Safety: Low in volatile organic compounds (VOCs), making it a safer option for installers and environmentally friendly.

Applications:

Sports Fields: Ideal for securing synthetic turf in football, soccer, and multi-sport fields, providing a stable and reliable surface for athletic activities.

Landscaping: Perfect for residential and commercial landscaping projects where artificial grass is used to enhance aesthetic appeal and functionality.

Playgrounds: Suitable for playground installations, ensuring a safe and durable surface for children’s play areas.

Recreational Areas: Used in various recreational and leisure areas to create low-maintenance, visually appealing, and long-lasting synthetic turf surfaces.

Technical Specifications:

Components: Resin (Part A) and Hardener (Part B).

Mix Ratio: Typically mixed at a specific ratio as recommended by the manufacturer to ensure optimal performance.

Color: Usually available in a green or clear color to blend seamlessly with artificial grass.

Viscosity: Medium viscosity for easy mixing and application.

Working Time: Provides sufficient working time after mixing to allow for precise installation.

Cure Time: Fast curing, with initial set time within a few hours and full cure achieved in 24-48 hours, depending on temperature and humidity.

Benefits:

Durable Bond: Ensures a long-lasting and stable bond, maintaining the integrity of the synthetic turf installation over time.

Easy Application: Simple mixing and application process, suitable for professional installers and DIY projects alike.

Enhanced Aesthetic: Seamlessly integrates with artificial grass, providing an invisible bond that enhances the overall appearance.

Cost-Effective: Reduces the need for frequent maintenance and replacement, offering cost savings over the lifespan of the installation.

Safe and Eco-Friendly: Low VOC content promotes a healthier environment for installers and end-users.

Summary:

N TURF 19 Multipurpose Two-Component Artificial Grass Adhesive is an ideal choice for securing synthetic turf in a variety of settings. Its robust bonding capabilities, resistance to weather conditions, and ease of application make it a preferred solution for creating durable and aesthetically pleasing artificial grass surfaces. Whether used in sports fields, landscaping, playgrounds, or recreational areas, N TURF 19 ensures reliable performance and long-term durability.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Packaging Type | HDPE Barrel |

| Application | Laminating |

| Application Industry | Joint filling |

| Surface Of Application | Metal |

| Form | Liquid |

| Grade Standard | Industrial |

NEOSOL PU Binder is a high-performance polyurethane binder designed for use in creating synthetic sports surfaces, particularly running tracks. Here’s a detailed description of NEOSOL PU Binder:

Product Overview:

NEOSOL PU Binder is a versatile, high-quality, and durable polyurethane-based adhesive. It is specifically formulated to bond EPDM granules and other rubber particles, providing a resilient and long-lasting surface suitable for various athletic and recreational activities.

Key Features:

Exceptional Adhesion: Offers superior bonding capabilities, ensuring that the granules are securely held together, which enhances the longevity and durability of the sports surface.

Elasticity and Flexibility: Maintains excellent flexibility and elasticity, allowing the surface to absorb impacts effectively, reducing stress on athletes' joints.

Weather Resistance: Designed to withstand a wide range of weather conditions, including UV exposure, temperature fluctuations, and moisture, without degrading.

Environmental Compatibility: Formulated to be environmentally friendly, with low VOC (Volatile Organic Compounds) content, making it a safer choice for installers and users.

Easy Application: Can be easily mixed and applied, ensuring a smooth and even coating over the granules for consistent surface quality.

Applications:

Running Tracks: Ideal for creating all-weather running tracks that offer consistent performance and safety.

Playgrounds: Suitable for use in playground surfaces where safety and durability are paramount.

Sports Courts: Can be used for various sports courts, including tennis and basketball, where a durable and high-performance surface is required.

Multi-Purpose Athletic Fields: Perfect for multi-use athletic fields, providing a versatile and resilient surface for various sports.

Technical Specifications:

Base: Polyurethane

Color: Typically clear or slightly amber, allowing the color of the EPDM granules to show through.

Viscosity: Medium to high viscosity for optimal application and bonding.

Cure Time: Fast-curing properties to ensure quick installation and minimal downtime.

Shelf Life: Generally, a shelf life of around 12 months when stored in optimal conditions (cool and dry).

Benefits:

Enhanced Safety: Provides a cushioned and non-slip surface, reducing the risk of injuries.

Low Maintenance: Once cured, the surface requires minimal maintenance, making it cost-effective over its lifespan.

Aesthetic Appeal: Helps in creating visually appealing surfaces with vibrant colors and consistent texture.

NEOSOL PU Binder is the preferred choice for constructing high-performance and durable athletic surfaces, ensuring that athletes can train and compete on the best possible tracks.

| Business Type | Manufacturer, Exporter, Supplier |

| Size | Etc |

| Thickness | 3.2~5mm |

| Capability | Nonpoisonous Substance, Resistance Of Aging |

| Warranty | More than 12 months |

| Application | For Mixing The Rubber Granule |

| Surface | Smooth or cloth wove |

Rubber granule binders are specialized adhesives used to bond rubber granules together, creating resilient and durable surfaces for various applications. These binders ensure a strong and flexible bond, ideal for constructing sports surfaces, playgrounds, and safety flooring.

Key Features:

Strong Adhesion: Provides excellent bonding strength, ensuring rubber granules are securely held together for a durable surface.

Flexibility: Maintains flexibility, allowing the surface to absorb impacts and reduce stress on users' joints.

Weather Resistance: Formulated to withstand various weather conditions, including UV exposure, moisture, and temperature fluctuations.

Quick Curing: Fast curing times facilitate quicker installation and reduce downtime.

Low VOC: Environmentally friendly with low volatile organic compound content, ensuring safety for installers and end-users.

Applications:

Sports Surfaces: Ideal for creating durable and high-performance running tracks, tennis courts, and other athletic surfaces.

Playgrounds: Suitable for constructing safe and resilient playground surfaces, providing cushioning and injury reduction.

Safety Flooring: Used in safety flooring for industrial and commercial areas where slip resistance and impact absorption are critical.

Rubber Paving: Perfect for creating rubber-paved paths, walkways, and other decorative outdoor surfaces.

Summary:

Rubber granule binders are essential adhesives that provide strong, flexible, and weather-resistant bonds for rubber granule surfaces. These binders are crucial in constructing safe, durable, and high-performance surfaces for sports, playgrounds, safety flooring, and rubber paving, ensuring long-lasting performance and environmental safety.

| Business Type | Manufacturer, Exporter, Supplier |

| Color | Multi |

| Size | 1520*650*1160mm |

| Max length | 420MM ( A3,A4 ) |

| Max thickness | 58mm |

| Binding speed: | 200-300 books/H |

| Clip length | 370MM |

Special binders are advanced adhesives formulated for specific and demanding applications, ensuring strong, durable, and specialized bonds. These binders are tailored to meet the unique requirements of various industries, providing optimal performance under specific conditions.

Key Features:

High Bond Strength: Delivers exceptional adhesion, ensuring reliable and robust bonding for diverse materials.

Tailored Formulations: Custom-designed to meet the specific needs of different applications, such as resistance to heat, moisture, chemicals, or UV light.

Versatility: Suitable for a wide range of substrates, including metals, plastics, rubber, wood, and composites.

Durability: Engineered to withstand challenging environments and prolonged use, maintaining bond integrity over time.

Special Properties: May include properties like flexibility, electrical conductivity, thermal resistance, or quick curing, depending on the application.

Applications:

Electronics: Used in assembling and bonding electronic components, requiring precision and reliability.

Automotive: Ideal for applications in the automotive industry, such as bonding parts that endure high stress and temperature variations.

Construction: Suitable for construction applications where strong, weather-resistant, and durable bonds are essential.

Aerospace: Used in the aerospace industry for high-performance bonding that can withstand extreme conditions.

Medical Devices: Designed for medical device assembly, ensuring biocompatibility and safety.

Summary:

Special binders are high-performance adhesives designed for specific applications, providing tailored solutions that meet the unique demands of various industries. With features like high bond strength, tailored formulations, versatility, and durability, these binders are essential for achieving reliable and specialized bonds in electronics, automotive, construction, aerospace, and medical applications.

- It is the polymeric from polyether polyol and isocyanate,

- It has a strong adhesive force with the broken pieces of the sponge,

- It is the professional adhesive for every high-low density renewable sponges,

- It has unique characteristic of being speed adjustable, easy to use and non-toxic.

- Different Binder grades available to achieve varied strength properties

- Suitable for a wide range of products and applications like rebonded foam, rebonded rubber etc.

- It can be applied in any way known to those skilled in the art of preparing rebonded foam either in a stream or as an aerosol.