- Nehru Place, Delhi

- View Mobile Number

| Business Type | Manufacturer, Exporter, Supplier |

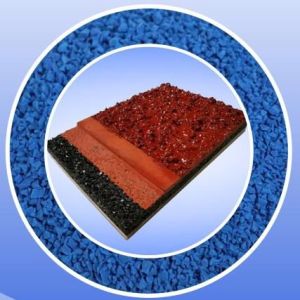

2 Component Spray Coat Systems for Running Tracks

Description-

Overview

N-Track 64 is an advanced, two-component spray coating system designed specifically for the construction and maintenance of running tracks. This system provides a seamless, durable, and high-performance surface that meets the rigorous demands of athletic activities. It is ideal for professional sports facilities, schools, and recreational areas.

Key Features

1. Durability:

o Wear Resistance: Formulated to withstand heavy foot traffic and athletic activities, ensuring a long-lasting surface.

o Weather Resistance: Excellent resistance to various weather conditions, including UV radiation, rain, and temperature fluctuations.

2. Safety:

o Slip Resistance: Provides a non-slip surface, reducing the risk of injuries for athletes.

o Impact Absorption: Designed to absorb impact, minimizing stress on athletes' joints and muscles.

3. Performance:

o Consistent Surface: Ensures a smooth and consistent running surface for optimal athletic performance.

o Excellent Traction: Offers superior grip, enhancing athletes' performance and reducing the likelihood of slips.

4. Aesthetic Appeal:

o Color Options: Available in various colors, allowing for customization to match team or facility colors.

o Finish Quality: Delivers a high-quality finish that enhances the visual appeal of the track.

5. Environmental Resistance:

o Waterproofing: The spray coating provides excellent waterproofing, protecting the underlying surface from moisture damage.

o Chemical Resistance: Resistant to common chemicals and substances, ensuring longevity and low maintenance.

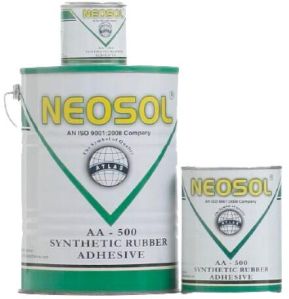

System Composition

1. Component A:

o Typically a polyol blend that acts as the reactive base of the coating system.

2. Component B:

o Generally an isocyanate that reacts with Component A to form a durable polyurethane coating.

Application Process

1. Surface Preparation:

o Cleaning: Ensure the existing surface is clean, dry, and free from dust, dirt, oil, and other contaminants.

o Priming: Apply a primer if necessary, to enhance adhesion between the existing surface and the new coating.

2. Mixing:

o Component Mixing: Mix the two components (A and B) according to the manufacturer’s instructions, ensuring thorough mixing for a consistent and reactive blend.

3. Application:

o Spray Application: Use a specialized spray equipment to apply the mixed coating onto the track surface. Ensure even and consistent application to achieve the desired thickness.

o Layering: Multiple layers may be applied to achieve the required surface properties and thickness.

4. Curing:

o Setting Time: Allow the coating to set and cure according to the specified curing time. Avoid any traffic or movement on the track during this period.

o Final Inspection: After curing, inspect the track surface to ensure complete and even coverage, making any necessary touch-ups.

- Benefits

- Longevity: The durable formulation provides a long-lasting surface that can withstand intense use and various environmental conditions.

- Low Maintenance: The high resistance to wear, weather, and chemicals means less frequent repairs and maintenance.

- Enhanced Performance: Offers a safe and consistent surface that helps athletes perform at their best.

- Aesthetic Quality: Maintains its appearance and functionality over time, enhancing the overall look of the track facility.

- Technical Specifications

- Mixing Ratio: Specified by manufacturer (typically 1:1 or as recommended).

- Pot Life: Adequate working time for application (varies based on environmental conditions).

- Curing Time: Typically ranges from several hours to a day, depending on temperature and humidity.

- Application Temperature: Recommended temperature range for optimal performance.